Applications

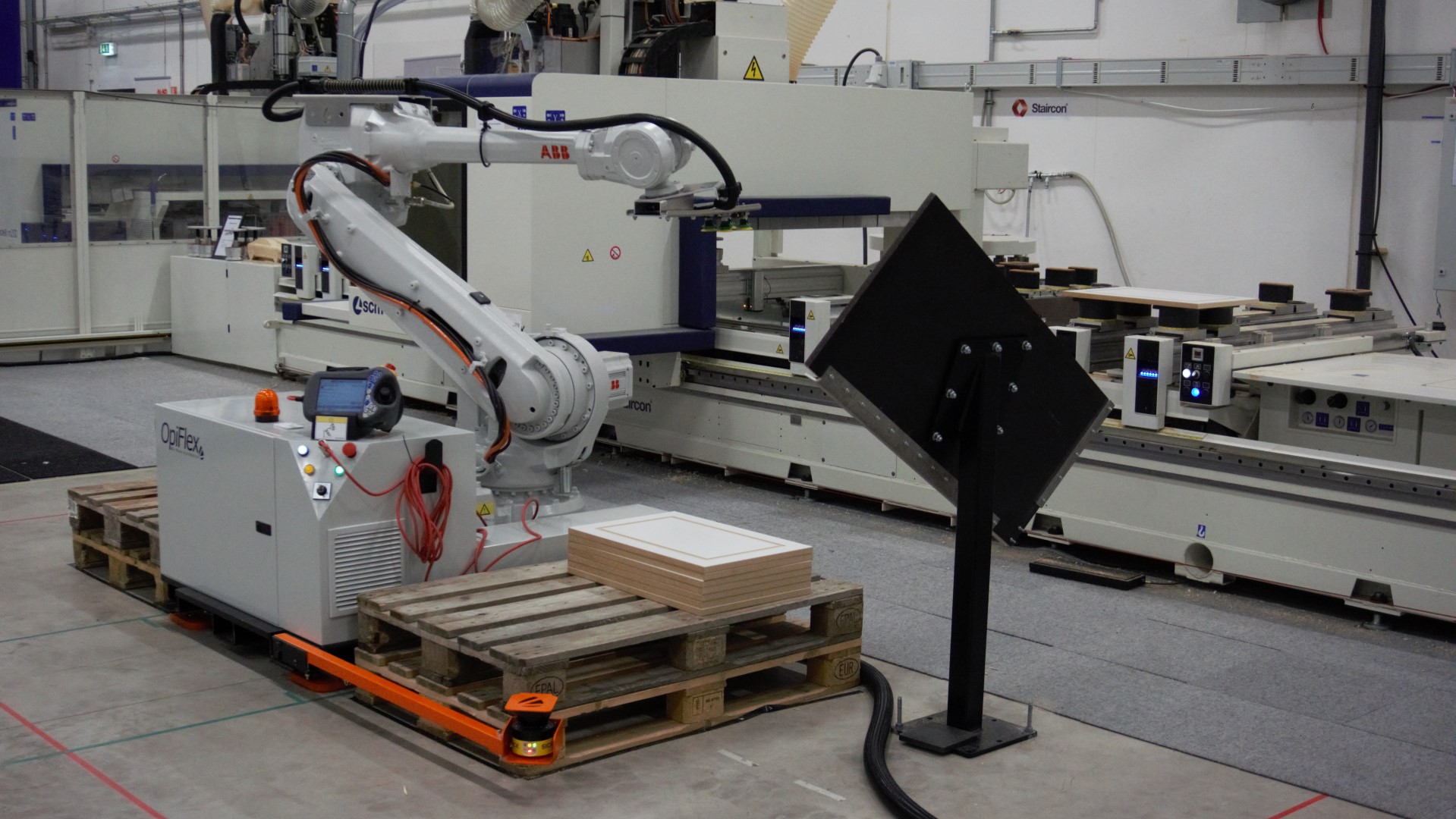

OpiFlex solves the challenge of automating the new mega trends with high mix and low volume in all industries, such as wood, metal, construction, food and plastics. OpiFlex is future-proof and runs the third robot revolution and is demanded by both small and medium-sized companies but also large global corporations

Mix of applications

SICK about OpiFlex Fanceless Safety

Customer example – Press Brake

Where is OpiFlex used?

Små-medelstora företag

Underleverantör

Globala Koncerner & OEM

Machine Tending

Material Handling

Palletizing

Assembly

When is OpiFlex used?

Low and unevenly used machines

Small series and high mix and low volume

Flexible lines and robot cells

High volume and high availability

Industries

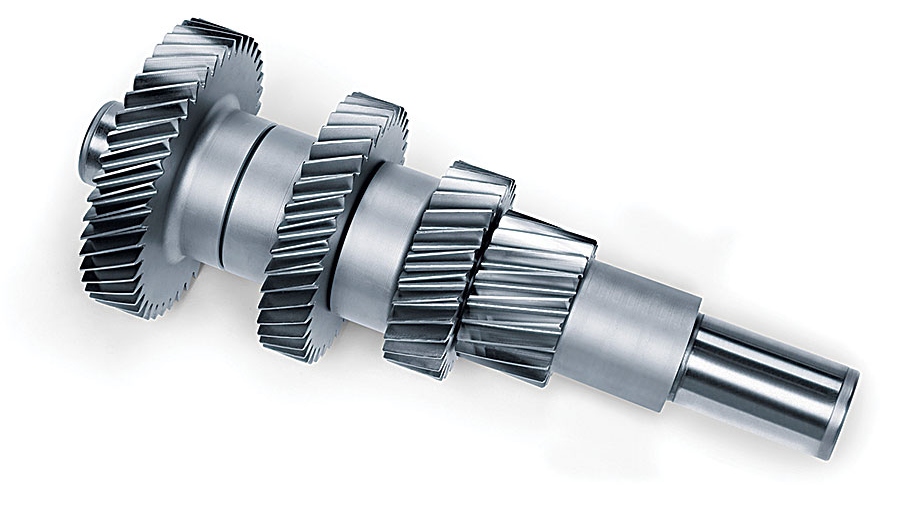

Metal

OpiFlex's very flexible solutions fit everything from machining to sheet metal forming, material handling and assembly.

Automotive

OpiFlex skapar nya möjligheter på alla platser, t ex i början, mitten eller slutet av lina för ökad flexibilitet hos både TIer1, OEM och biltillverkare.

Wood & Furniture

OpiFlex creates new opportunities to automate the wood industry for both small subcontractors and large furniture companies.

Food & Beverage

OpiFlex creates completely new possibilities with flexible automation of lines, such as lines that do not go all the time or where different configurations or quick adjustments are needed.

Plastic

OpiFlex creates new opportunities where flexible automation is needed in part and the rest is released into pallets.

General

OpiFlex's unique flexibility creates new possibilities for automation in most areas, contact us and we can see opportunities.