The contracting company IS Plåt in Vellinge made a robot lift and invested three flexible robot cells from OpiFlex. With the help of OpiFlex and the robot lift, they can now automate small series production. In an article in Svensk Verkstad, IS Plåt’s CEO Erik Ralvert is interviewed about how they thought.

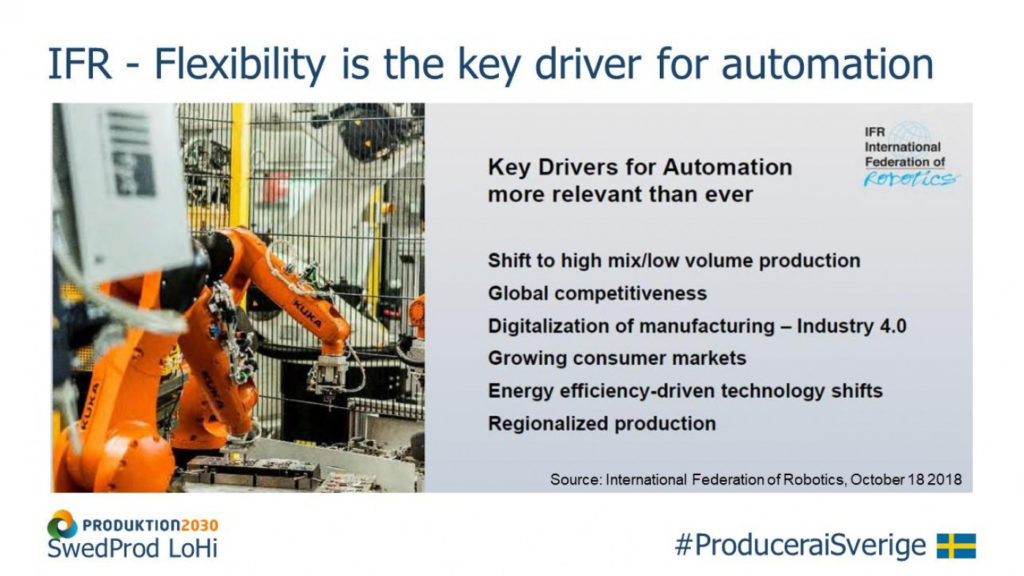

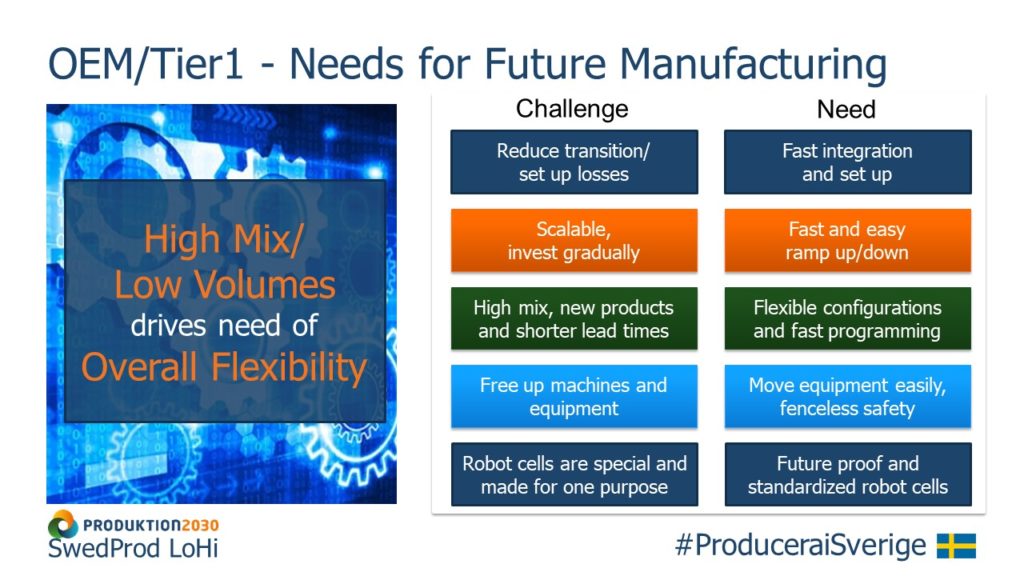

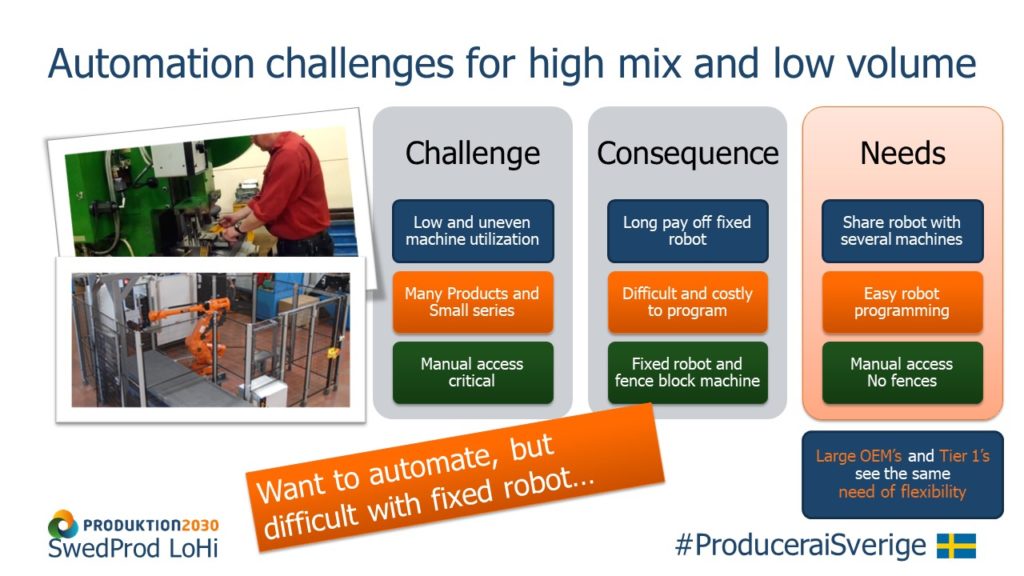

High mix and low volume are a major trend in the manufacturing industry and the demands for increased productivity and flexibility are also increasing for contract manufacturers. Automating the business is a path to increased competitiveness, but for many the step feels big and you do not really know where to start.

The most important thing to be able to automate is flexibility

They talk about how they need a flexible solution to automate. They want to find

- staff and be able to motivate them

- a future-proof solution that also helps in the short term

- ergonomic solutions

- something that increases productivity by running the robot on the machine with the highest occupancy without buying more robots

Read more about their needs and how it was solved in Svensk Verkstad’s article.

Get help thinking in new directions

IS plate got a lot of help to think in new paths. In the article, they describe all the steps and how they were helped to think in new directions. Much was through OpiFlex expert help, heavily discounted automation analyzes through the robot lift.

The article also describes their needs and thoughts in detail as well as information about the robot lift and automation checks and guides. Read more in the article!

About IS Plåt who need OpiFlex solutions

The family company IS Plåt is a contract manufacturer with 50 employees. Specializing in stainless steel, the company manufactures, on behalf of its customers, many different products in small series. The customers are mainly in the water treatment and packaging industry. Over the years, the company has grown, among other things through acquisitions. Today, laser cutting, bending, welding, turning, milling and surface treatment have been gathered under their own roof. They do not have to lay out, but can do everything themselves.