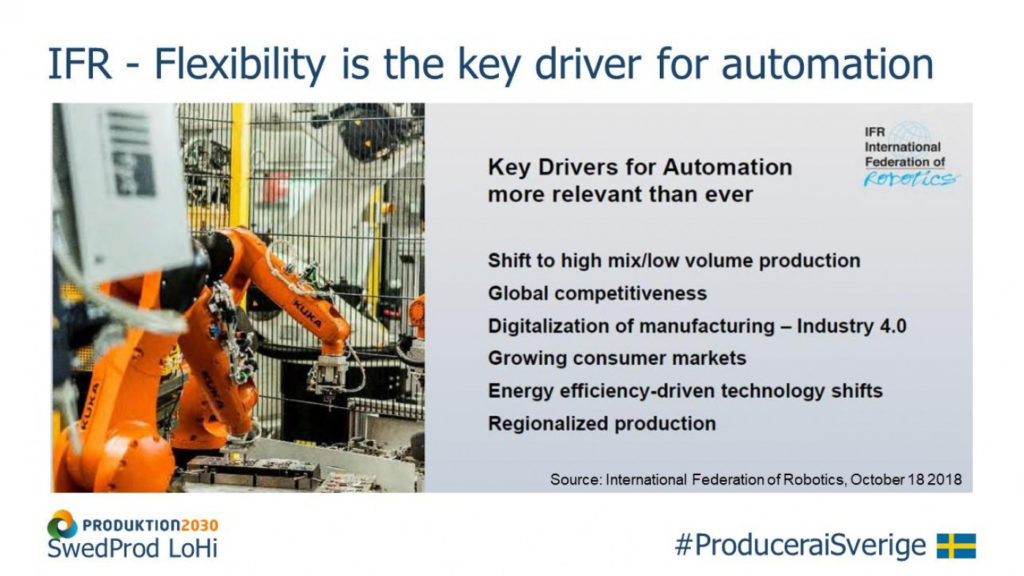

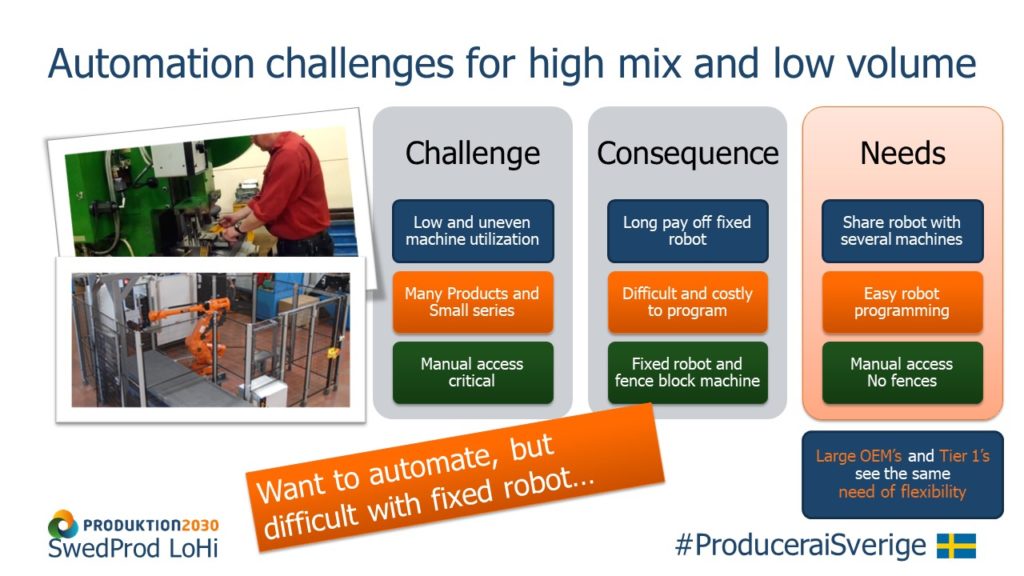

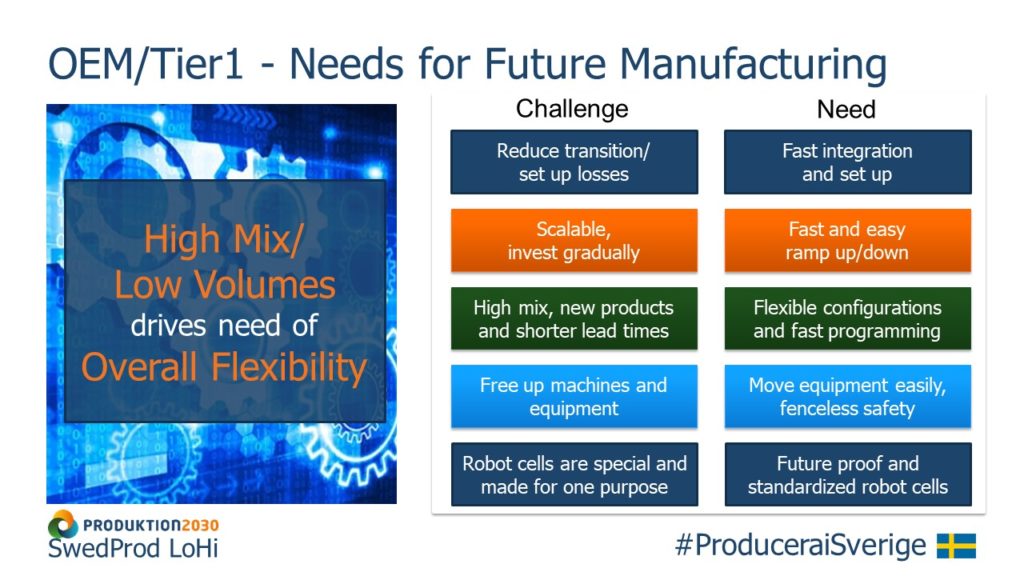

We see more and more large OEM and Tier1 groups need more flexibility. This is seen e.g. the car industry, electronics industry, white goods, etc. that are driven by shorter series and higher mixes and where overall flexibility becomes more important to them. Many large OEMs have seen a challenge of increased automation as they “locked themselves in” with traditional fixed robot cells with fences as it is difficult to adapt these for new products or just to change the layout in the workshop.

Based on interviews and discussions with more than 30 global OEM and Tier1 groups in various industries such as the automotive, electronics, white goods, consumer goods and furniture industries, the following five common challenges and needs have emerged:

Five common challenges

- Fast integration and installation – they want it to go fast, a few days instead of a few weeks, to speed up conversion and avoid lost production.

- Fast and easy up and down ramp of production – they want to be able to ramp up and down production with flexible solutions so that they can make better use of investments and adapt production for new products.

- Flexible configurations and fast programming – they want to be able to change quickly, so that they can adapt production for new products and mix many products in the same line / machine.

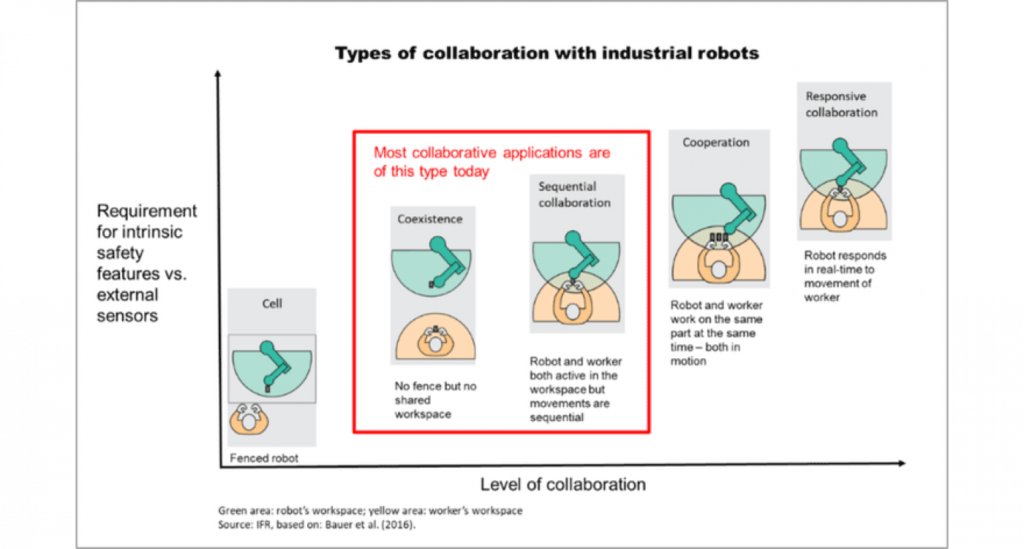

- Change layout easily and avoid fences – they want to avoid fences so that they can quickly move machines and lines with its robot cells, so that they are not locked in a certain layout.

- Future-proof and standardized solutions – as the product mix increases, the robot cells need to be easily reused and then flexible solutions that are standardized are desired. Mobile robots are not a fixed asset, which provides new opportunities for flexibility.

In summary – OEM and Tier1 groups need more flexibility. All these points, OpiFlex solutions help you with thanks to their solutions. These are mobile robots for different cells but with the same performance, simple programming and safety without fences. Read more about OpiFlex applications

How to automate high mix and low volume in small series production

Read more about how to automate high mix and low volume in small series production in our comprehensive guide “How to automate high mix and low volume production”