The Ministry of Enterprise and Innovation in Sweden has been on a visit to OpiFlex offices. They follow the project Produce in Sweden which aims for a sustainable and profitable small series production. Now the production in Sweden has started: “It is important to show subcontractors that have extremely short planning horizons and very jerky production that it is possible to increase productivity much. With a short pay-off. “

Unless the smaller companies in Sweden automate, competitors will do it

– Ministry of Sweden

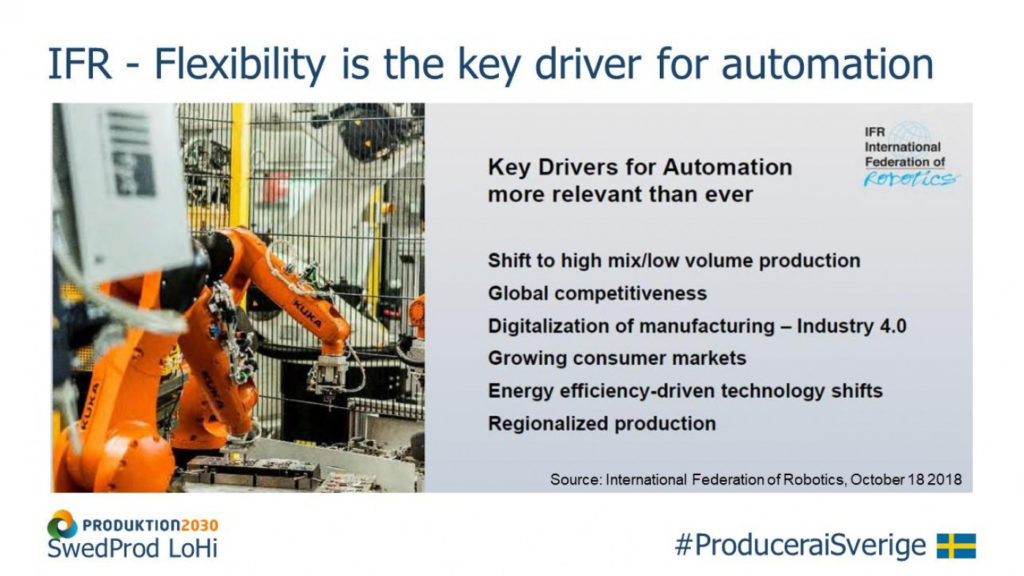

Today everyone is agreed that automation is necessary for the survival of Swedish industry and the path to increased competitiveness with the goal of getting home jobs to Sweden.

This is also underlined by the digitalisation that all industries are subject to at the moment.

For industry, this is obvious, and at the same time we are pleased to see how the government focuses on industry and its digital conversion under the heading “Smart industry – a Nyindustrialiseringsstrategi for Sweden”.

The activity in ministry is febrile about these issues and not least Karin Azade, Department council and head of Unit for enterprise and entrepreneurship and Johan Harvard, project manager for Samverkansprogrammet connected industry in the same Unit is deeply involved in the digitisation of industry.

They are enthusiastically following the project producing in Sweden, initiated by Johan Frisk, CEO of OpiFlex Autmation AB and now led by Swerea IVF AB where Boel W is Project manager.

Produce in Sweden – Followed by the Ministry of Enterprise and Innovation in Sweden

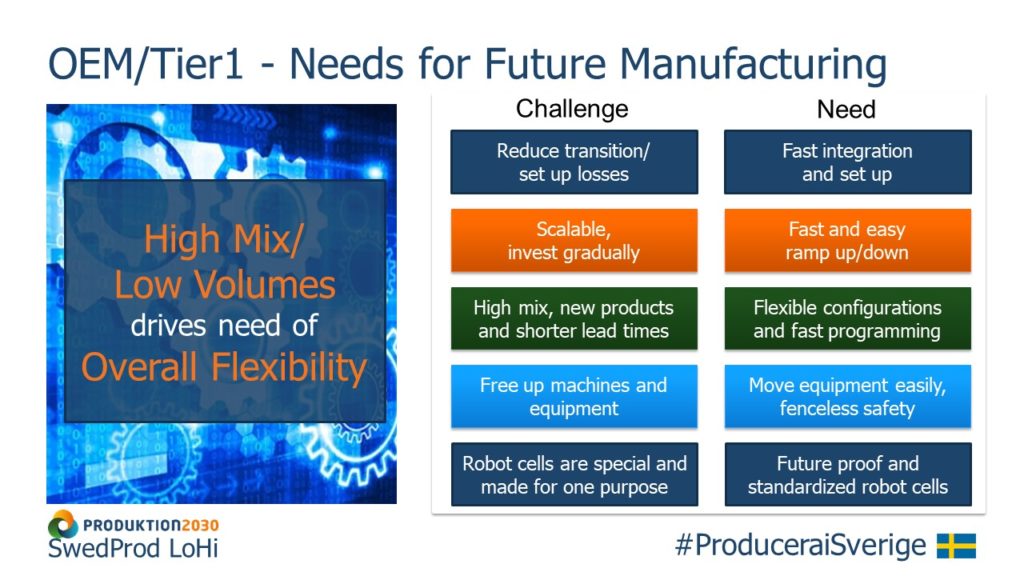

The core of the project producing in Sweden is to show that we can have a sustainable and profitable small series production in Sweden and it rhymes very well with the government’s intentions in Nyindustrialiseringsstrategin.

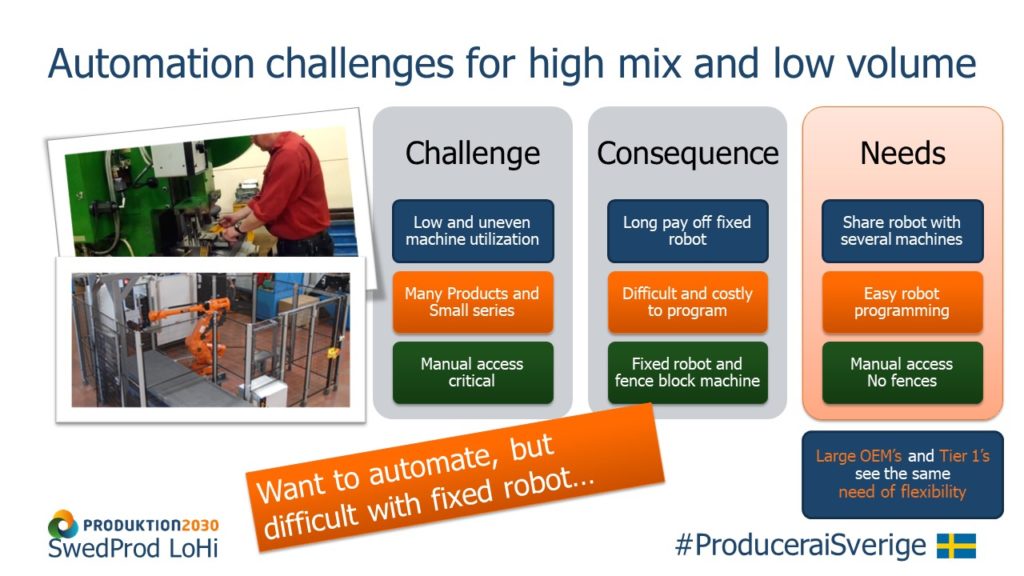

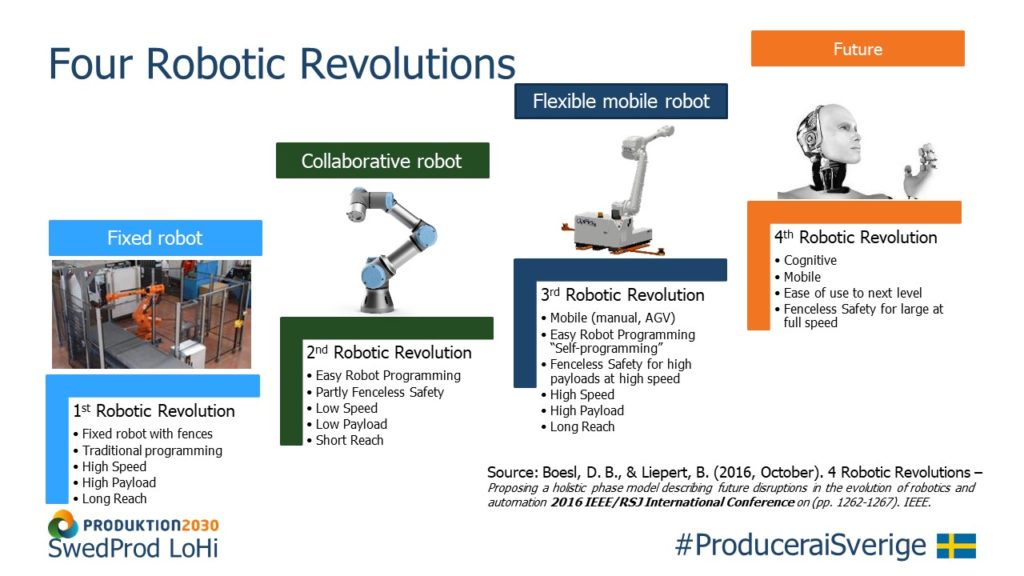

Historically, it was difficult to make a profitable and efficient way to automate production in small series. But it’s history.

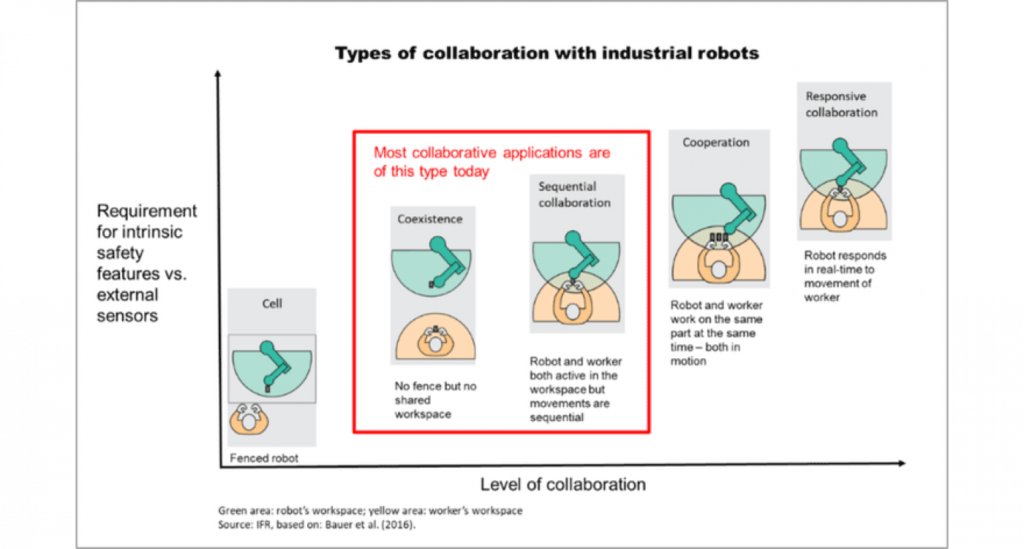

For example, OpiFlex has solved several problems that create new opportunities for this with its mobile robot system for larger robots, which can withstand safety without fences and which also makes programming easy.

“When even bureaucrats can program a robot in ten minutes, they have come a long way,” says Karin Azade, the Department council.

Department unit for Business and entrepreneurship recently made a study visit to OpiFlex in Västerås and three of the delegation left the company with a diploma in robot programming.